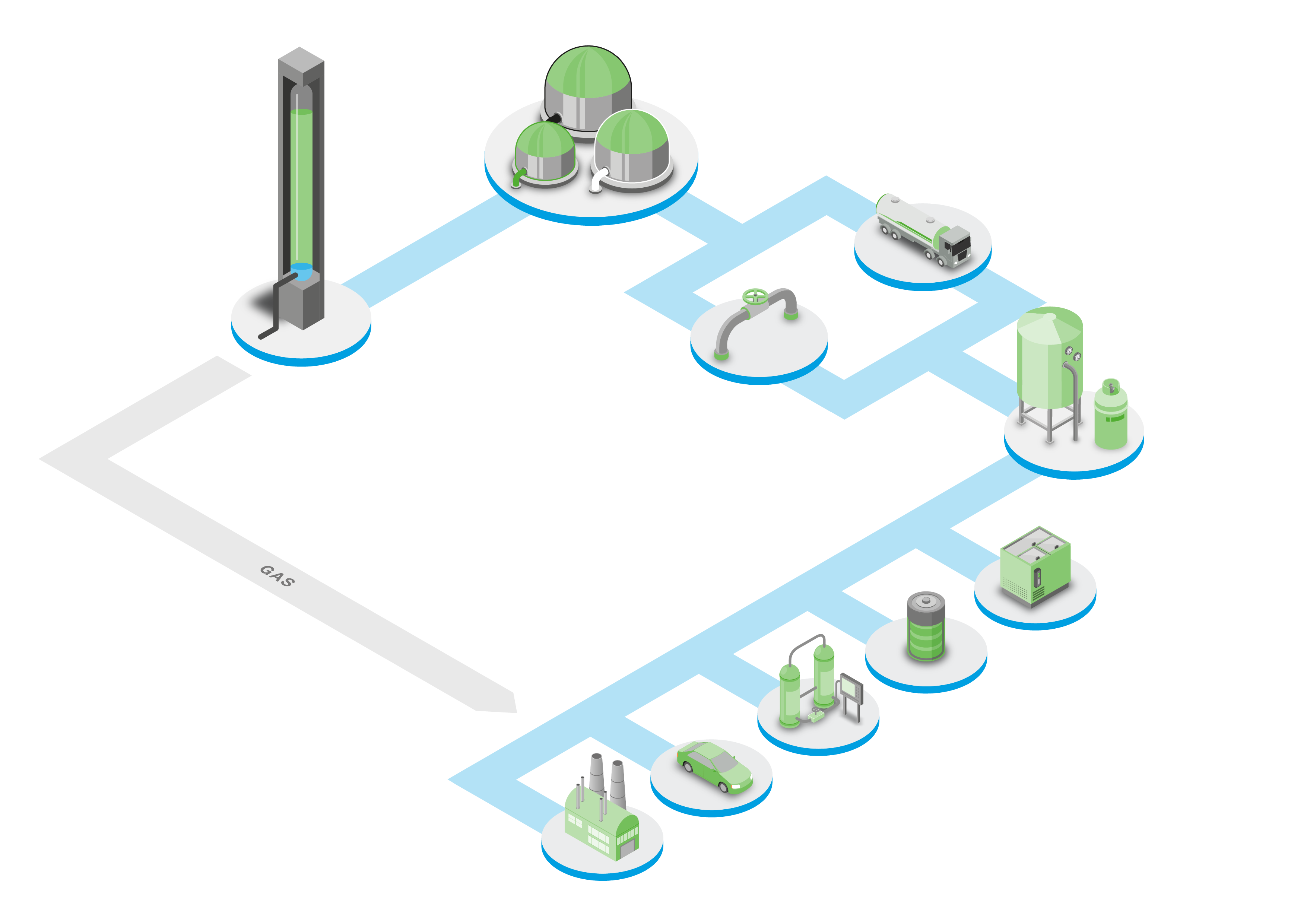

Many gases surround us every day. These can be used for different processes. However, in order to use them effectively and economically, they are often liquefied at cryogenic temperatures.

"Constant innovations and modern valve technology help to supply the world with air gases safely."

Industrial gases

value chain

- Technical gases such as oxygen, nitrogen and argon can be liquefied at cryogenic temperatures

- When liquefied at cryogenic temperatures, the volume of industrial gases is reduced by a factor of up to 600, making it an economical solution for transport and storage.

- HEROSE offers you valve packages all along the value chain for air gases

- We adapt products that have already proven themselves many times to target specifications or the special circumstances of your project.

We are offering solutions in this areas

-

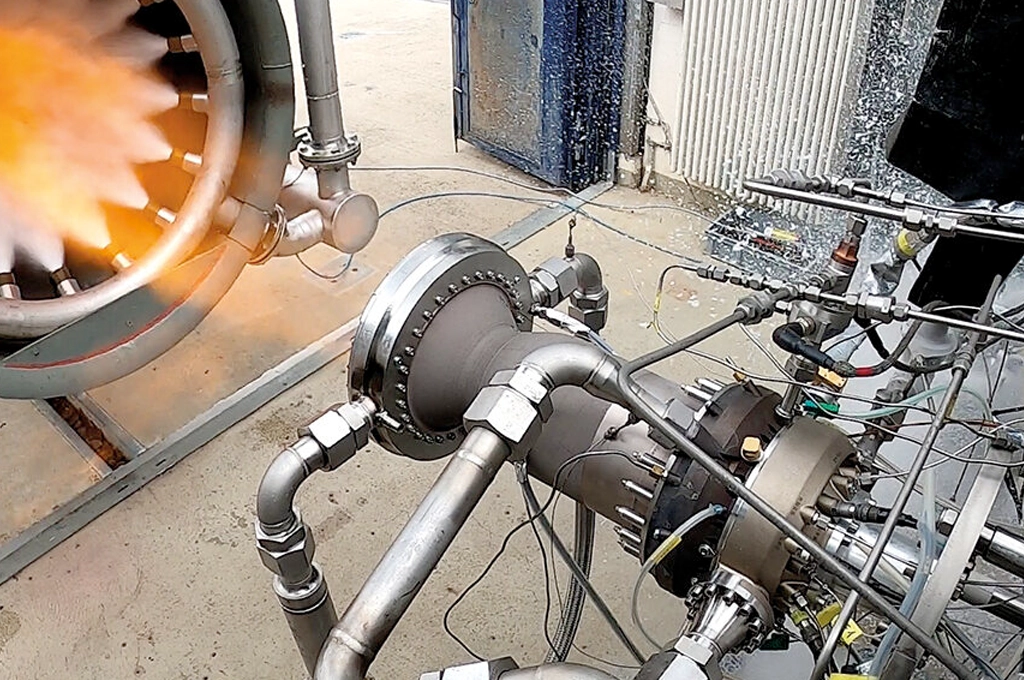

Processes

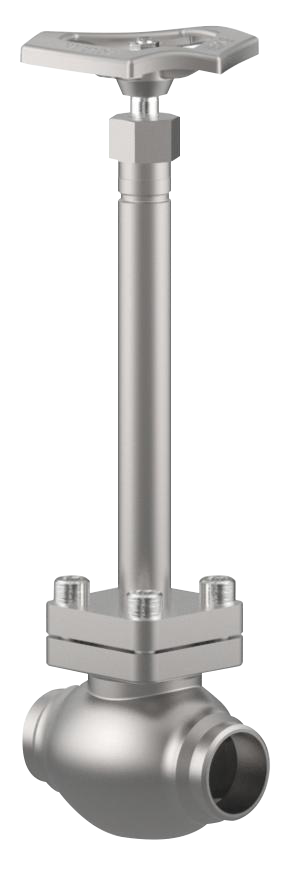

In order to industrially produce nitrogen, oxygen, argon and other air gases in high-purity concentrations, the individual air components are separated from one another in a thermal process in air separation plants. The necessary maintenance and repair work in the cold box is significantly simplified by the HEROSE top-entry valves.

-

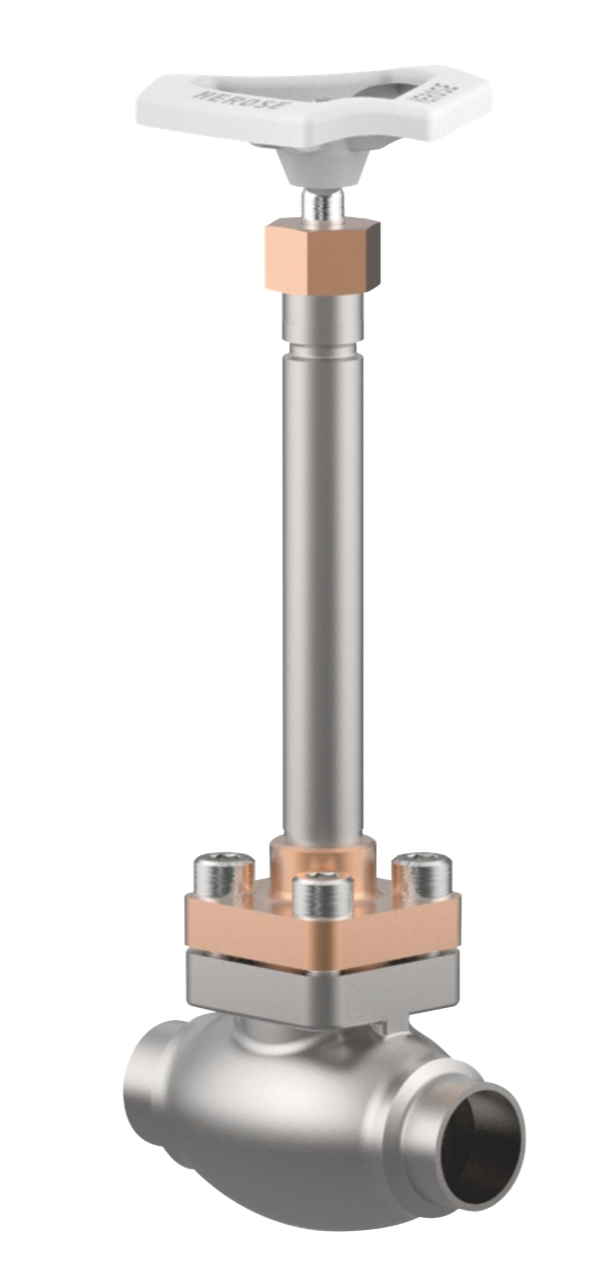

Transport

Technical gases are liquefied at cryogenic temperatures and transported from the air separation plant to the customer in special tankers. The payload can be increased thanks to the weight-reduced valves from HEROSE.

-

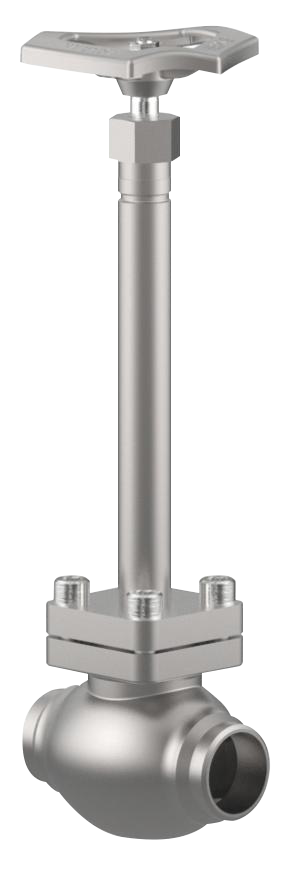

Storage

Depending on the purchase quantity, cryogenic liquefied air gases are stored in stationary storage containers from 3,000 to 100,000 l. Compact filling modules from HEROSE ensure comfortable and safe handling during the filling process.

Wiki Base

Did you know?

HEROSE has the right product so that every element finds its way

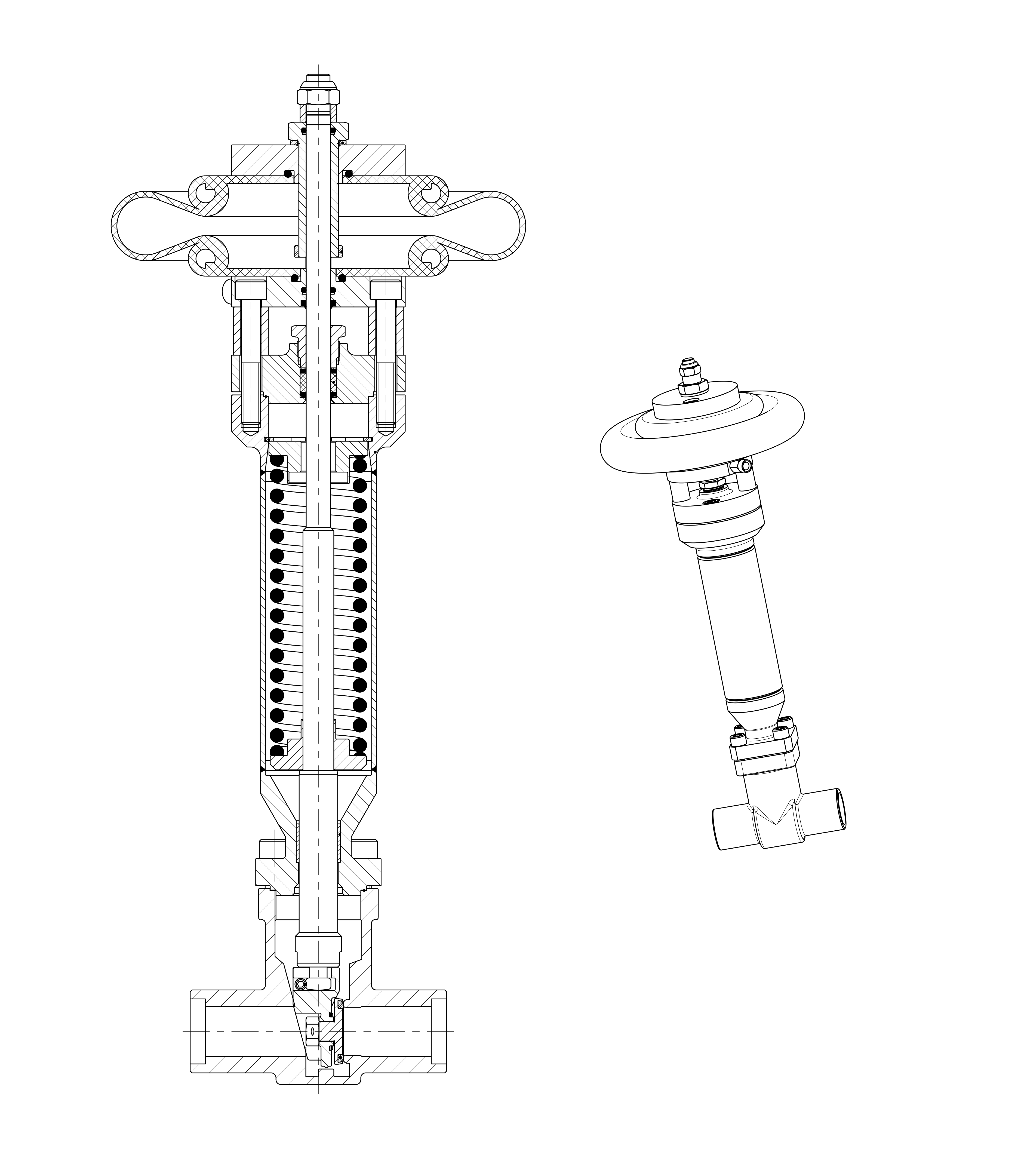

Technical gases can be generated by various processes. Oxygen, nitrogen, argon and noble gases in air separation plants, hydrogen by electrolysis, helium from natural gas, among other things. HEROSE supplies high-quality cold-box valves and control valves for this purpose to control the operation of the plants and to regulate and thereby ensure that the air is broken down both in the desired amount and at the desired pressure.

In air separation, air is divided into its components. The different boiling temperatures of the gases form the basis for the gas separation. For large purchase quantities, customers use their own air separators instead of storage tanks.

HEROSE valves and fittings help ensure the safety and reliability of the systems.

Cryogenic areas of application include the food industry, welding and laser technology, medicine, shipbuilding, pharmacy and many more.

Everything goes to the right place with HEROSE valves

In order to get technical gases from the production site to the customer, they are transported either via pipelines or cryogenically liquefied by truck on public roads in special vacuum-insulated containers or tanks. In the vacuum space between the inner and outer tank, MLI insulation is preferably used here (multi layer isolation). The volume is the lowest here and at the same time there is a weight saving compared to e.g. Perlite.

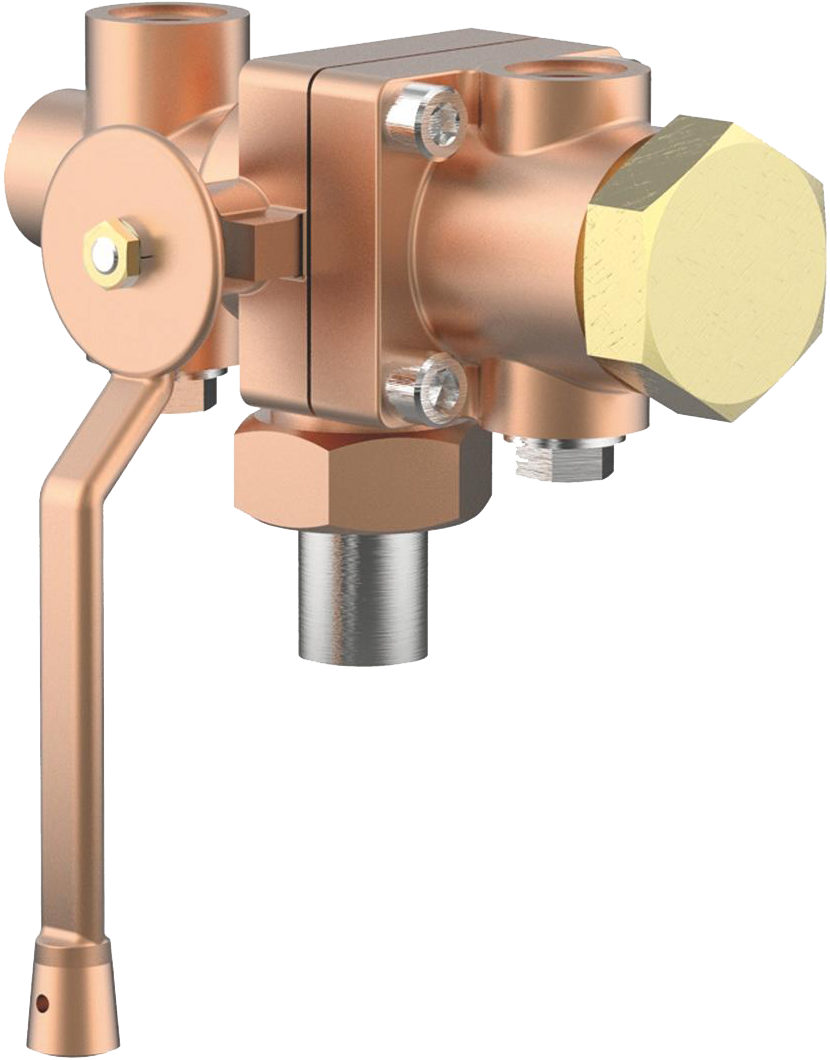

Valves and fittings help to ensure safe and reliable operation of the transport containers. They are used to fill the respective customer tank with the required quantity of the gas to be transported, depending on the operating pressure. Valves, such as the HEROSE shut-off valves and actuated valves, help to ensure that transport is safe and reliable. Since these valves are used very frequently for filling and discharging, they are exposed to the toughest conditions.

HEROSE valves keep everything in the right place

In stationary containers, cryogenic liquefied industrial gases can be stored for further distribution without major evaporation. The cryogenic liquefied product is mainly stored in vacuum-insulated containers under customer-specific overpressure. In contrast to the transport containers, the vacuum space is usually filled with perlite. In the case of discontinuous acceptance by of the customers, overflow valves or pressure regulators are used to maintain the operating pressure before the main safety valves prevent impermissible pressure excesses.

Different container sizes (from 5,000 to 50,000 liters capacity) are used depending on the quantity and frequency of the customer's purchase.

The wide range of products from HEROSE offers the right fittings for every tank. These are used as intended and meet the respective requirements of the area of application.