As the most common chemical element in the universe, hydrogen is playing an increasingly important role in sustainable energy supply. The requirements for conversion and use are challenging and the demands on quality and security are extremely high. With our high-performance valves for the most diverse areas of application of hydrogen use, you are on the safe side with HEROSE.

Hydrogen is new in many areas. HEROSE valves undergo extensive testing to ensure hydrogen suitability, including material tests, leak tests and pressure tests. Therefore we can guarantee the usual HEROSE quality for our hydrogen valves.

Hydrogen

value chain

- Hydrogen (H2) is a carbon-free energy carrier that provides the opportunity to reduce worldwide greenhouse gas emissions, energy security for counties with high demand, and profitable export of energy by countries with excess of renewable electricity.

- To fulfil this promise hydrogen can be produced from renewable power (solar, wind, hydro-power), but also from nuclear electricity or from biomass and fossil energy sources when carbon is sequestered (CCS/CCU: Carbon Capture and Storage or Use).

- To enable efficient storage and transport, the volumetric energy content of the hydrogen must be increased. This can be done by compression or liquefaction, but also by by attaching hydrogen to other substances , for example using liquid organic hydrogen carriers (LOHC), ammonia (NH3) or metal hydride storage materials (MHx).

- Finally, at the point of use, hydrogen (or hydrogen carrier) can be used directly or converted back to electricity.

- HEROSE offers hydrogen compatible valves are for all parts of the value chain

We are offering solutions in this areas

-

Production

Safety valves to protect your electrolyser from over-pressure, from atmospheric alkaline to high-pressure PEM and from laboratory to GW range.

-

Transport & storage

Cryogenic safety valves and flow control valves for hydrogen liquefaction and liquid transportation up to DN 200 (8“)

-

End Usage

High-pressure safety valves for trailer and vehicle filling up to 550 bar and development of individualised safety and flow valves

Wiki Base

Did you know?

HEROSE has a safety valve for every size of electrolyser

Electrolysers produce hydrogen and oxygen from water and (renewable) electricity. They often operate at elevated pressure to facilitate hydrogen storage and transport.

Safety valves usually open around 10% above the working pressure to prevent damage to equipment and people. The safety valve directs the hydrogen or oxygen released to a venting system.

The valve capacity must be large enough to relief the maximum possible flow after an equipment failure.

Electrolyser modules are often connected to build plants in the 100 MW range.

Our large capacity valves, for example valve 06383 with 23 mm flow diameter, are suitable for these plants.

For smaller pressurized electrolysers smaller valves are sufficient, for example valve 06012 with 6 mm flow diameter.

Hydrogen safety valves for transport and storage

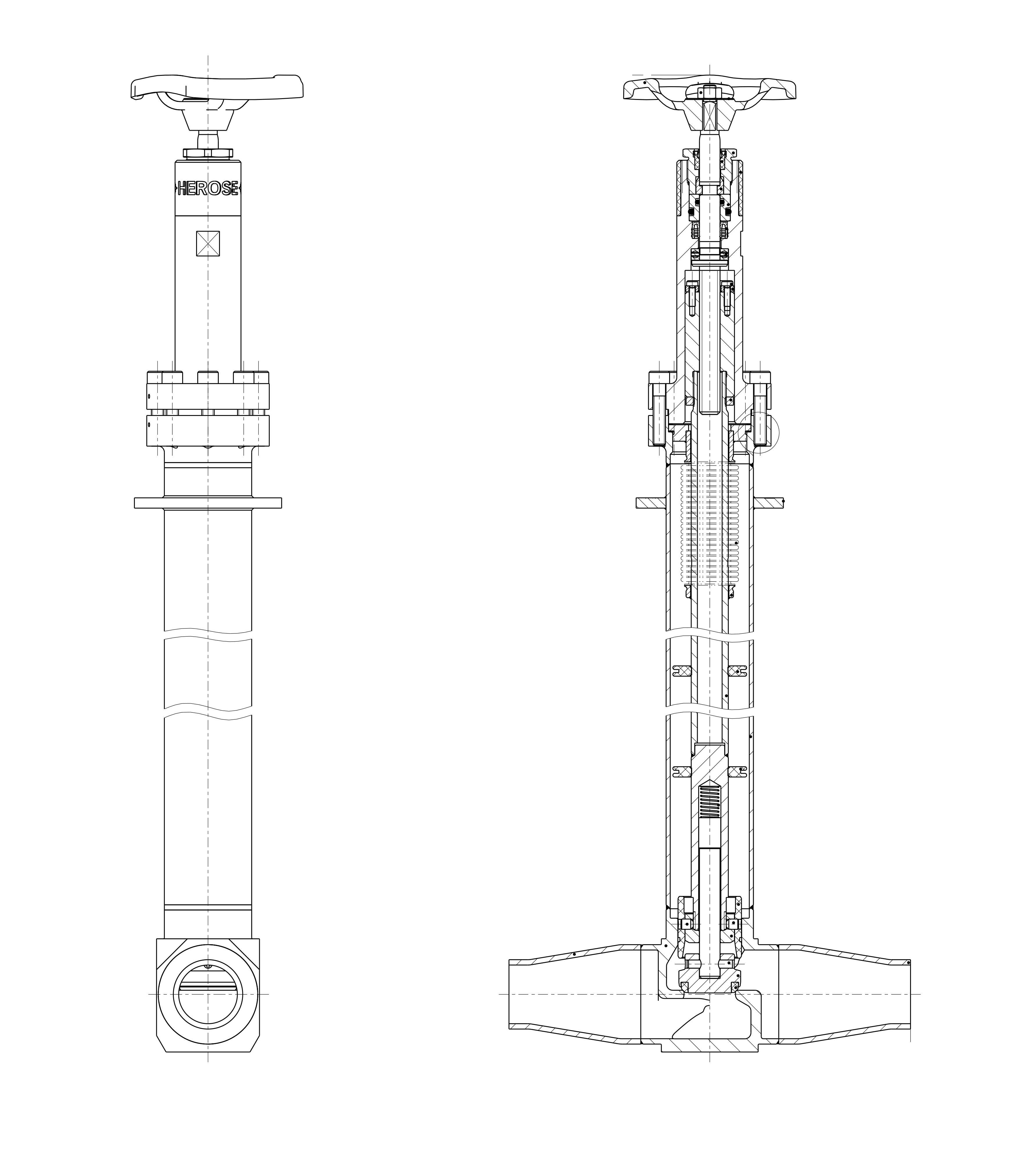

Hydrogen is likely to be produced at locations with abundant renewable electricity, making liquefaction a viable option for transport. HEROSE supplies cryogenic globe valves, check valves and filters for liquefaction, storage and transport by ship and trailer.

At the destination, where hydrogen is regasified, the FullX globe valve can be deployed at liquid hydrogen temperature but also for gaseous hydrogen at 63 bar pressure.

Our cryogenic safety valves can even be used up to 550 bar pressure for subsequent compression to transport the hydogen via pipeline or trailer or for underground storage.

Special ships and tankers are used for transporting LNG from the liquid gas storage facilities to the satellite stations of the users. HEROSE supplies the suitable shut-off valves for liquid hydrogen according to DIN EN 12567.

Extensive solutions of HEROSE for various applications

To increase the amount hydrogen tank that can be stored in a tank, it is sometimes compressed to very high pressure. HEROSE 06810 and 06820 safety valves have been extensively used up to 550 bar and proven very reliable.

A product range extension to 1000+ bar is under development.

HEROSE is further investigating the adaptation of valves for larger hydrogen mobility applications like trucks, ships and aircraft. An example is a safety valve for use on trains, developed in cooperation with Anleg.