- Home

- › Products

- › Cryogenic

- › Globe Valves

CRYOGENIC

Type 01321 - Globe Valve

|

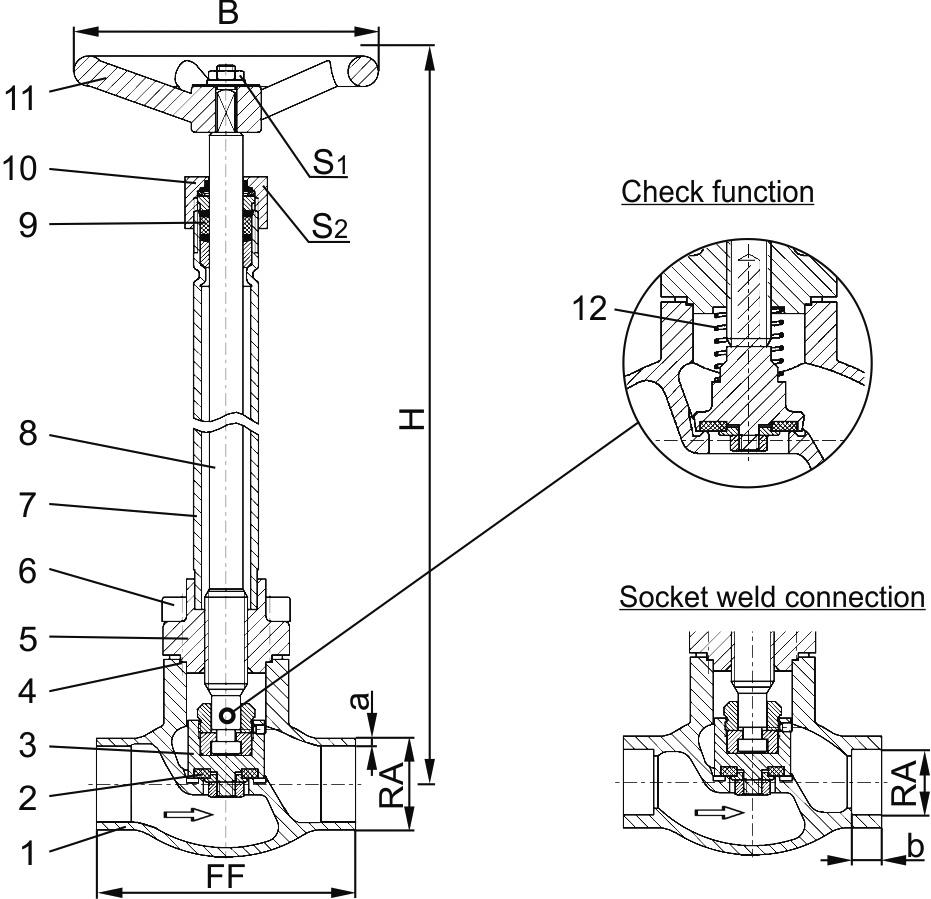

Cryogenic-Globe and Globe/Check Valves, PN50 (DN65=PN45, DN150=PN40) Stainless steel body and bronze topwork "live loaded" gland packing "cleaned and degreased for oxygen service" Part No. 01321.X.001* (H = 270mm) Part No. 01321.X.002* (H = 370mm) Part No. 01321.X.501* (H = 270mm) Globe/Check Valve Part No. 01321.X.502* (H = 370mm) Globe/Check Valve *Butt weld connection for stainless steel pipes acc. to ISO 1127 or ASTM A312 Part No. 01321.X.0014 (H = 270mm) Part No. 01321.X.0024 (H = 370mm) Part No. 01321.X.5014 (H = 270mm) Globe/Check Valve Part No. 01321.X.5024 (H = 370mm) Globe/Check Valve Socket weld connection for stainless steel pipes acc. to ISO 1127 or ASTM A312 Available options - on request only: - Welded stainless steel stubs acc. to ISO 1127 or ASTM A312 - length FF + 200mm - Extension H up to 900mm - Valve with control disc (tapered design) - Further pipe wall thicknesses Applications: Approved for air gases, vapours and cryogenic liquefied gases incl. LNG. Working temperature: -196°C / -321°F (77K) up to +120°C / +248°F (393K) |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type 01321 - Standard design | Technical data | |||||||||||||

| Nominal size | DN | 10 | 15 | 15 | 20 | 25 | 32 | 40 | 40 | 50 | 65 | 80 | 100 | 150 |

| Dimension code | .X. | 1012 | 1517 | 1521 | 2026 | 2533 | 3238 | 4042 | 4048 | 5060 | 657x | 8088 | 0114 | 0168 |

| Face-to-face dimension | FF | 70 | 85 | 85 | 100 | 115 | 115 | 130 | 130 | 155 | 205 | 245 | 280 | 400 |

| Height | H | 270mm or 370mm | 320/370 | 320/370 | 370 | 420 | ||||||||

| Outside pipe-Ø ISO 1127 | RA | 12.0 | 17.2 | 21.3 | 26.9 | 33.7 | 38.0 | 42.4 | 48.3 | 60.3 | 76.1 | 88.9 | 114.3 | 168.3 |

| Wall thickness pipe ISO 1127 | a | 1.0 | 1.6 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.9 | 3.2 | 6.0 | 7.1 |

| Outside pipe-Ø ASTM A312 | RA | 13.72 | 17.15 | 21.34 | 26.67 | 33.40 | - | 42.16 | 48.26 | 60.32 | 73.02 | 88.90 | 114.30 | 168.27 |

| Wall thickness pipe ASTM A312 | a | dimensions acc. to S10 or S40 | ||||||||||||

| Socket depth | b | 6 | 10 | 10 | 13 | 13 | - | 13 | 13 | 16 | 16 | 16 | 20 | 20 |

| Handwheel-Ø | B | 100 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | 200 | 250 | 315 | 360 |

| Wrench size across flats | S1 | 7 | 7 | 7 | 7 | 7 | 10 | 10 | 10 | 10 | 10 | 10 | 12 | 15 |

| Wrench size across flats | S2 | 30 | 30 | 30 | 30 | 30 | 36 | 36 | 36 | 36 | 36 | 36 | 41 | 41 |

| Weight | ca. kg | 1.4 | 1.65 | 1.7 | 2.1 | 2.4 | 3.3 | 4.7 | 4.7 | 5.7 | 12.7 | 17.0 | 24.5 | 54.0 |

| Kvs-Value | m³/h | 1.6 | 3.8 | 4.3 | 6.7 | 11.5 | 14.0 | 20.6 | 22.6 | 37.1 | 71.1 | 104.0 | 170.0 | 350.0 |

| Cv-Value | gal/min | 1.9 | 4.4 | 5.0 | 7.8 | 13.4 | 16.2 | 23.9 | 26.3 | 43.2 | 82.9 | 121.3 | 198.3 | 408.4 |

| Dimensions in mm. Compliance of tightness requirements acc. to EN 1626 for DN150 up to 20 bar differential pressure. In the range of >20-40 bar, 350-700ml per second (1 bar, 20°C [68°F]) are reached. |

- Type 28311 - Topwork

- Type 28203 - Disc complete

- Type 28203, 28205 - Check Disc complete

- Type 30000 - Sealing spare part kit

- Type 31514 - KEL-F (PCTFE) Disc sealing spare part kit

- Type 50155 - Anti-icing shield

- Type 55317, 55318 - Handwheel

- Type 55579 - Valve locking

- Type 66394 - Alcatraz-Valve locking